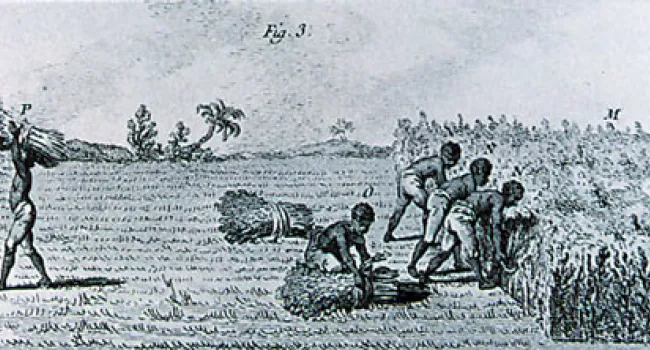

This engraving, also from the 1785 Henry Mouzon map cartouche shows all the main steps in the production of indigo. The plants were harvested in bundles before the stems became woody, then immediately soaked in vats of water, where they quickly fermented in the summer heat. The foul-smelling fermented liquid was then drained off into a second set of vats, where it was beaten with paddles to stir air into the mixture and speed up the oxidation process. When small particles of a blue precipitate formed, the beating stopped, the dye master let the particles settle to the bottom of the vat, and the liquid was drained off the top into another vat. The blue mud-like sludge at the bottom of the second vat was then shoveled into sacks to squeeze out liquid, was dried, and cut into small cubes and packed in barrels for shipment to England. Production of indigo created enormous wealth for many South Carolinians in the last half of the 18th century, particularly in the Winyah Bay area of Georgetown. The American revolution made indigo less profitable, because it ended both the English bounty system and access to the English market to sell it.

Courtesy of the Charleston Museum, Charleston, South Carolina.